Email: ashley@numa-tech.com

Email: sales@numa-tech.com

The healthcare industry is in a constant state of evolution, with technological advancements reshaping the way medical professionals deliver care. One often overlooked but critical aspect of healthcare is inventory management, particularly in the realm of medical tools and equipment. Proper inventory management is essential for ensuring that healthcare providers have the necessary tools on hand to provide quality care while minimizing waste and cost. This is where Direct Part Marking (DPM) code readers step in to transform the management of medical tool inventories.

In this article, we will explore the significance of DPM code readers in the healthcare sector, their impact on inventory management, and the advantages they offer in enhancing efficiency, traceability, and patient safety.

The Challenge of Medical Tool Inventory Management

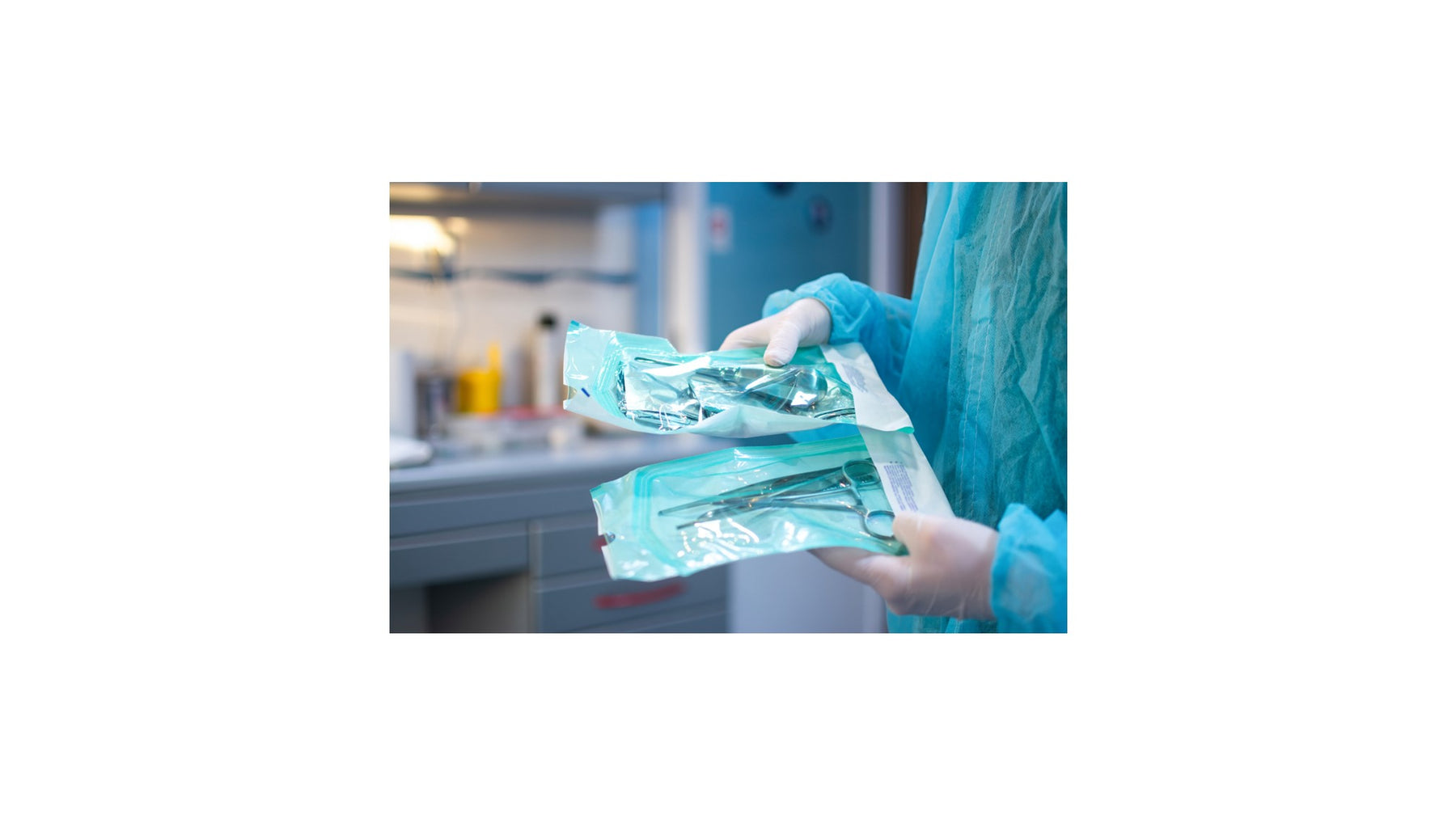

Healthcare facilities, from small clinics to large hospitals, are equipped with a multitude of medical tools and equipment that are essential for patient care. These tools include surgical instruments, diagnostic devices, monitoring equipment, and more. Keeping track of these items, ensuring their proper maintenance, and preventing loss or theft can be a daunting task. Traditional inventory management methods, such as manual record-keeping and barcode scanning, have limitations in terms of efficiency and accuracy.

Moreover, in healthcare, the stakes are incredibly high. Inaccurate inventory management can lead to dire consequences, including the potential for surgical errors, increased costs, and compromised patient safety. This is where DPM code readers come into play.

Direct Part Marking (DPM) Code Readers: A Game-Changer

DPM code readers are specialized devices designed to read and decode marks directly applied to an object's surface. In the context of medical tools, these marks are often Data Matrix codes, which are 2D barcodes that store critical information about the item, such as its serial number, manufacturing date, and maintenance history. Unlike traditional labels or barcodes, DPM codes are durable, tamper-resistant, and capable of withstanding the rigors of sterilization processes.

Here are some ways DPM code readers are transforming medical tool inventory management:

1. Enhanced Accuracy and Efficiency

DPM code readers provide a reliable and efficient means of tracking medical tools and equipment. By simply scanning the DPM code, healthcare providers can instantly access the item's history, eliminating the need for manual data entry and potential human errors. This streamlined process saves time, reduces administrative burden, and minimizes the risk of inaccuracies in inventory records.

2. Improved Traceability

One of the key advantages of DPM codes is their capacity to provide comprehensive traceability. Every tool's unique identification allows for tracking its entire lifecycle, from manufacturing and quality control to sterilization and usage. This traceability is invaluable in case of product recalls, ensuring that any affected items can be quickly identified and removed from circulation.

3. Increased Patient Safety

DPM code readers contribute to enhanced patient safety. The ability to verify the history and status of a medical tool before using it in a procedure ensures that only properly maintained and sterilized instruments are employed. This minimizes the risk of infections and other complications that can result from using inadequately prepared tools.

4. Reduced Operational Costs

Efficient inventory management leads to cost savings. By reducing the time and labor required for tracking and managing medical tools, healthcare facilities can allocate their resources more effectively. Moreover, the accurate tracking of tools minimizes the need for excessive safety stock, as providers can trust that the tools they have on hand are in optimal condition.

5. Compliance with Regulations

The healthcare industry is heavily regulated, and compliance with various standards and guidelines is essential. DPM code readers aid in meeting these requirements by ensuring that tools are properly documented, maintained, and checked for compliance. This helps healthcare facilities maintain accreditation and meet regulatory obligations.

6. Integration with Digital Systems

DPM code readers are often integrated with digital inventory management systems, allowing real-time updates and access to critical information. This connectivity enables healthcare providers to monitor their inventory remotely, make data-driven decisions, and plan for future needs more effectively.

Challenges and Considerations

While DPM code readers offer numerous advantages, their implementation requires careful planning. Facilities must invest in compatible marking and coding methods, ensure staff is trained to use the readers, and establish robust data management protocols. Furthermore, the initial cost of implementing DPM technology can be a barrier for some healthcare organizations, although the long-term benefits often outweigh this initial expense.

Must know features of the model DT-10

Must know features of the model DT-90

Conclusion

DPM code readers are revolutionizing medical tool inventory management in the healthcare sector. Their ability to enhance accuracy, traceability, and patient safety is invaluable, ultimately contributing to the delivery of higher quality care. By investing in DPM technology and embracing the benefits it offers, healthcare facilities can streamline their operations, reduce costs, and ensure compliance with industry regulations. DPM code readers are not just tools; they are a vital component in the ongoing evolution of healthcare, where precision and efficiency are paramount.

Find out more information of NUMA DPM code reader, please visit NUMA website https://www.numa-tech.com/en/product/detail/DT-90. Or please send your inquiry to sales@numa-tech.com for proposal and quote.